Interfacial properties alkyl polyglycoside derivatives.

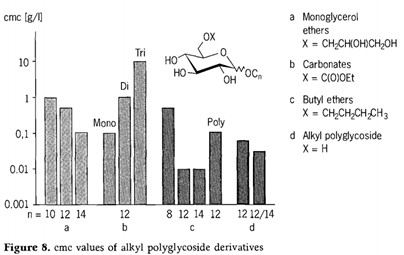

To characterize the interfacial properties of alkyl polyglycoside derivatives, surface tension/concentration curves were recorded and the critical micelle concentrations(cmc) and the plateau surface tension values above the cmc were determined from them. The interfacial tension against two model substances: octyl dodecanol and decane-were investigated as further parameters. The cmc values obtained from these curves are shown in Figure 8. the corresponding data for a C12 alkyl monoglycoside and a C 12/14 alkyl polyglycoside are included for comparison. It can be seen that alkyl polyglycoside glycerol ethers and carbonates have higher cmc values than alkyl polyglycosides of comparable chain length whereas the cmc values of the monobutyl ethers are somewhat lower than those of alkyl polyglycosides.

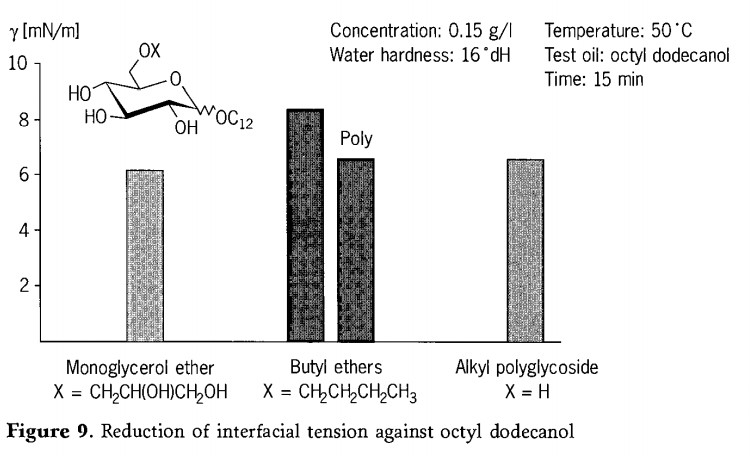

The interfacial tension measurements were carried out with a Kri.iss spinning drop tensiometer. To simulate practical conditions, the measurements were performed in hard water (270 ppm Ca :Mg= 5: ll at a surfactant concentration of 0.15 g/l and at SO Figure 9 shows a comparison of the interfacial tension of C12 alkyl polyglycoside derivatives against octyl dodecanol. The C12 mono[1]butyl ether has the highest interfacial tension and hence the lowest interfacial activity whereas the C12 monoglycerol ether is substantially at the level of the C12 polybutyl ether. The C12 alkyl polyglycoside included for comparison lies at the level of the last two alkyl polyglycoside derivatives mentioned. Overall, the interfacial tension values against octyl dodecanol are relatively high. This means that, for practical applications, it is important to ensure that the surfactant mixtures used have a synergism towards polar oils.

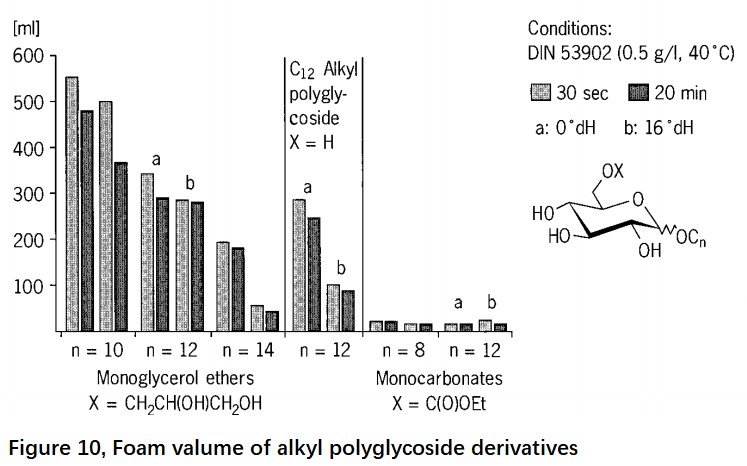

The foam test result as Figure 10.The foaming behavior of various alkyl polyglycoside monoglycerol ethers and monocarbonates was measured by comparison with C12 alkyl polyglycoside for two water hardness values in the absence of fatty soil. The measurements were conducted in accordance with DIN 53 902. The C10 and C12 alkyl polyglycoside monoglycerol ethers produced a larger foam volume than the C12 alkyl polyglycoside. Foam stability is significantly greater in the case of the C12 monoglycerol ether than in the case of the C10 derivative at 16°dH. The C14 alkyl polyglycoside monoglycerol ether does not compare with the C10and C12 derivatives in its foaming power and, overall, rates worse than the C12 alkyl polyglycoside. The mono-carbonates with alkyl chain lengths n of 8 and 12 are distinguished by very low foam volumes, as would be expected of a hydrophobic alkyl polyglycoside derivative.

Post time: Apr-26-2021