Alkyl glucoside or Alkyl Polyglycoside is a well-known industrial product and has been a typical product of academic focus on for a long time. More than 100years ago, Fischer Synthesized and identified the first alkyl glycosides in a laboratory, about 40years later, the first patent application describing the use of alkyl glycosides in detergents was filed in Germany. Thereafter the next 40-50years, some teams of companies turn their attention to alkyl glycosides and developed processes to produce them based on the synthesis methods Fischer discovered.

In this development, Fischer’s early work on the reaction of glucose with hydrophilic alcohols(such as methanol, ethanol, glycerol,etc.) was applied to hydrophobic alcohols with alkyl chains, ranging from octyl (C8) to hexadecyl (C16) the typical fatty alcohols.

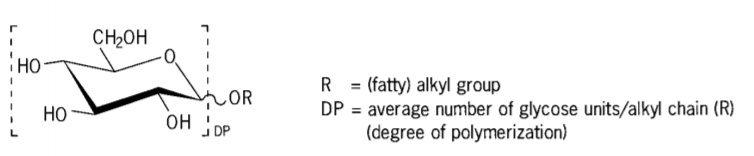

Fortunately, due to their application properties, the industrial production is not pure alkyl monoglucosides, but a complex mixture of alkyl mono-,di-,tri-and oligoglycosides, are produced in the industrial processes. Because of this, the industrial products are called alkyl polyglycosides, the products are characterized by the length of the alkyl chain and the average number of glycose units linked to it, the degree of polymerization.

(Figure 1. Molecular formula of alkyl polyglucosides)

Rohm&Haas was the first company to run mass production for octyl/decyl(C8~C10) glycosides in the late 1970s,followed by BASF and SEPPIC. However, due to the unsatisfactory performance of this short-chain and poor color quality, its application is limited to a few market segments, such as industrial and institutional sectors.

The quality of this shor-chain alkyl glycoside has been improved in the past few years and a number of companies are currently offering new octyl/decyl glycosides, including BASF,SEPPIC,Akzo Nobel, ICI and Henkel.

In the early 1980s, several companies began to develop alkyl glycosides in a longer alkyl chain range (dodecyl/tetradecyl, C12~C14) in order to provide a new surfactant for the cosmetics and detergent industry. They included Henkel KGaA,Diisseldorf,Germany,and Horizon, a division of A.E.Staley Manufacturing Company of Decatur,IIlinois,USA.

Using the Horizon know-how acquired at the same time, as well as Henkel KGaA’s experience from research and development in Diisseldorf. Henkel established a pilot plant to produce alkyl polyglycosides in Crosby,Texas. The production capacity of plant was 5000 t p.a., and has been trail run in1988 and 1989. The purpose of pilot-plant is to obtain process parameters and to optimize quality and cultivating market for this new surfactant.

During the period from 1990 to 1992, other companies announced their interest in producing alkyl polyglycosides (C12-C14),including Chemische werke Hiils, ICI,Kao,SEPPIC.

In 1992, Henkel established new plant in USA to produce Alkyl polyglucosides and its production capacity reached to 25000t p.a. Henkel KGaA started run second plant with same production capacity in 1995. Production capacity increase make new peaks of the commercial exploitation of alkyl polyglycosides.

Post time: Sep-12-2020